Welcome to Hebei Yunquan Pump Industry Co., LTD.

-

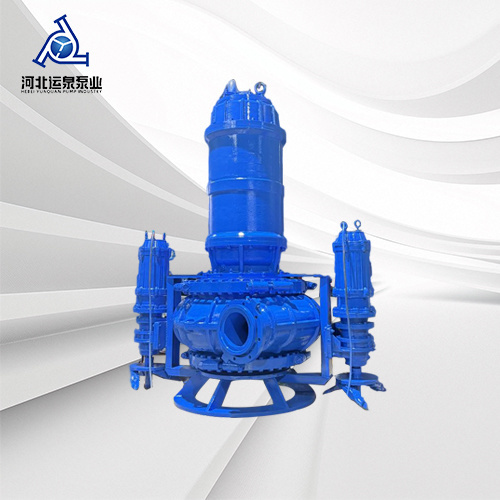

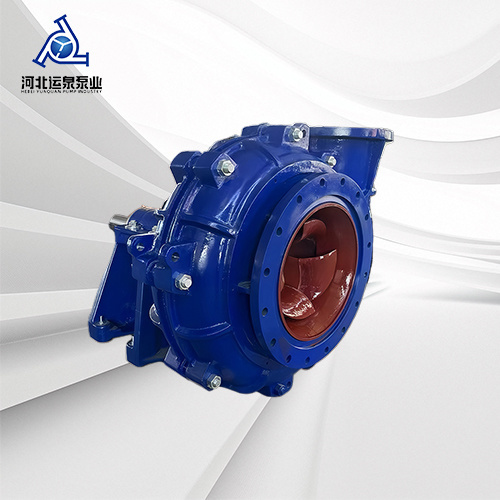

Horizontal Slurry Pumps

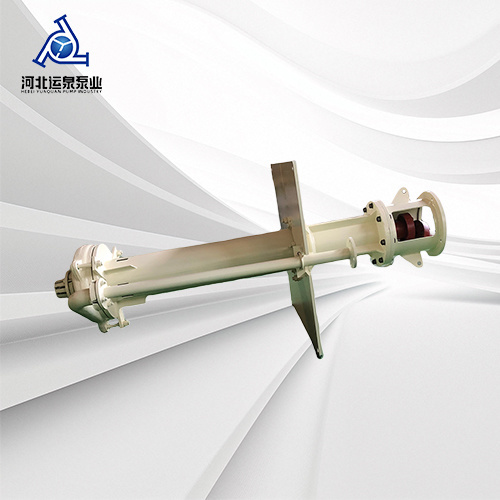

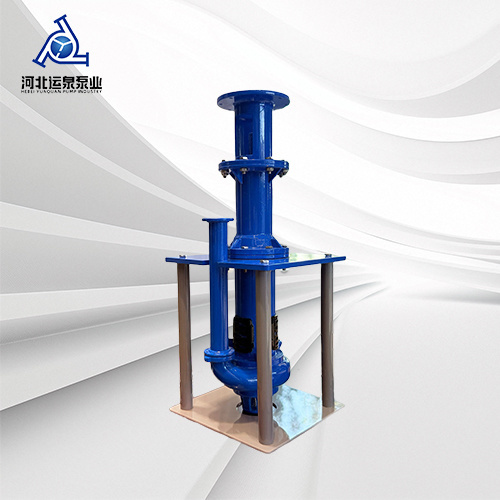

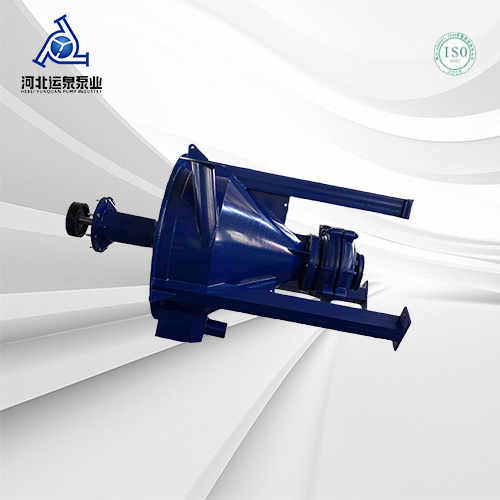

Vertical Slurry Pumps

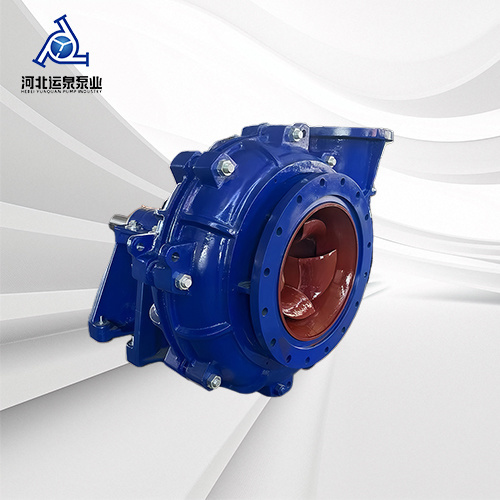

Gravel/Dredge Pumps

Froth Pumps

Pipeline pump

View Series Products

Selection and Maintenance of Foam Pump

Apr 18,2025

Key points of selection

Selection according to working conditions: according to the characteristics of the transmission medium (such as concentration, particle size, temperature, etc.) to select the appropriate foam pump type and material.

Consider the flow and head: determine the flow and head of the foam pump according to actual needs to ensure the normal operation of the equipment.

Choose reliable brands: give priority to manufacturers with rich experience and good reputation to ensure product quality and after-sales service.

Maintenance Points

Regular inspection: check the bearing temperature, vibration and noise to ensure normal operation.

Lubrication management: Replace the lubricating oil according to the specified period to ensure that the bearing is well lubricated.

Replacement of wearing parts: regularly check the wear of the impeller, guard plate, pump casing and other wearing parts, and replace them in time.

Cleaning and anti-corrosion: clean the inside of the pump body during shutdown to prevent the slurry from curing and blocking, and carry out anti-corrosion treatment on metal parts.

PREVIOUS:

Contact Us

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

ENQUIRY NOW