Share to

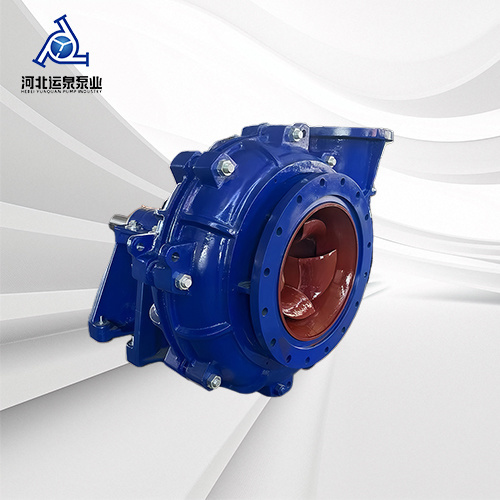

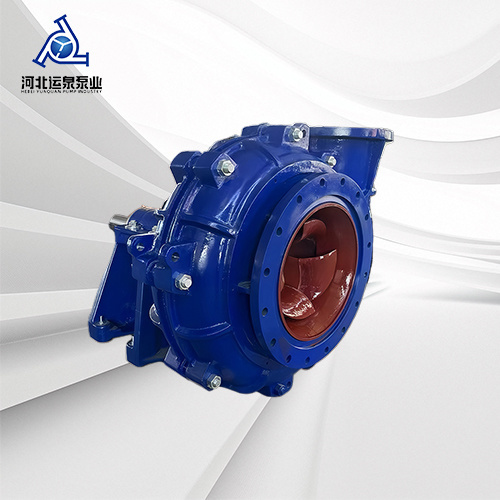

IMPELLER F6147

Extend pump life by selecting the right parts

Hotline:

86-18730251111

Still deciding? Get samples first, Contact US !

View similar products

Keyword

- Product description

-

Critical Wear Parts

These components require regular replacement due to abrasive wear:

Part Name Material Options Avg. Lifespan* Failure Symptoms Impeller High-Cr (A05, A49), Rubber, Ni-Hard 800-1,500 hrs Reduced head & flow Front Liner Cr15Mo3, Ceramic Composite 1,000-2,000 hrs Leakage at casing joints Back Liner Same as front liner 1,500-3,000 hrs Visible erosion marks Throat Bush Tungsten Carbide, SiC 2,000-4,000 hrs Increased shaft vibration Shaft Sleeve 316SS, Ceramic-coated 5,000+ hrs Seal leakage *Lifespan based on pumping silica slurry at 30% solids

Mechanical Components

Essential for pump operation and alignment:

Part Key Specifications Common Issues Shaft Assembly 420/431 SS, Hardened (>45HRC) Fracture near thread roots Bearings SKF/NSK 6316/C3 (grease-lubricated) Overheating (>85°C) Seal Housing ASTM A536 Ductile Iron Corrosion pitting Sealing Systems

Choose based on slurry characteristics:

Seal Type Pressure Limit Temp. Range Best For Expeller 8 bar -20~120°C Abrasive slurries Packing Gland 5 bar -10~80°C Cost-sensitive applications Double Mech Seal 25 bar -40~200°C Hazardous/toxic slurries Material Selection Guide

Choose based on slurry properties:

Slurry Characteristic Recommended Material High Abrasion (SiO₂) A05 High-Cr (27% Cr) Acidic (pH<4) Rubber-lined (Natural/Neoprene) Mixed Abrasion/Corrosion Ceramic-Filled Composite High-Temperature (>80°C) Ni-Hard 4

IMPELLER F6147

Extend pump life by selecting the right parts

Email:

Still deciding? Get samples first, Contact US !

View similar products

Keyword

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

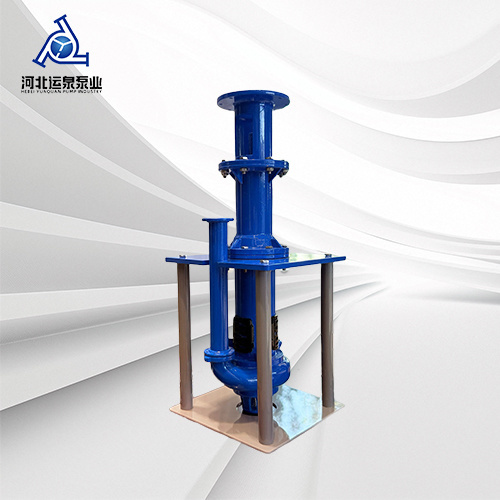

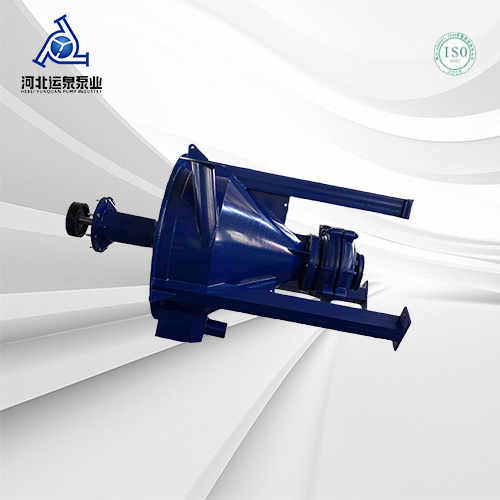

The ISG pipeline pump is a vertical inline centrifugal pump designed for clean water or slightly corrosive liquid transfer in HVAC, water supply, and industrial circulation systems.