Share to

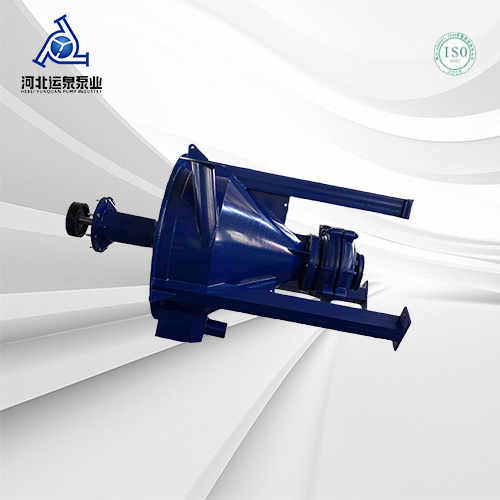

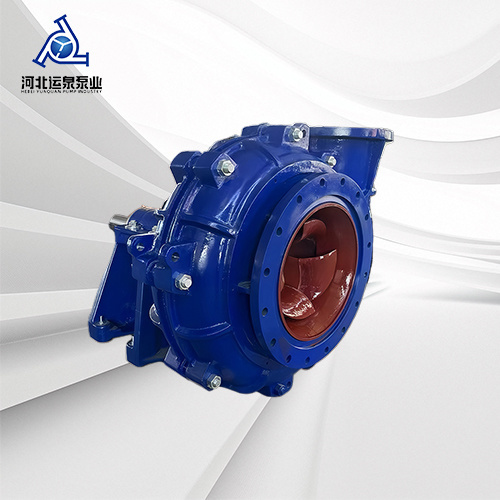

150ZJ-I-A50

Hotline:

86-18730251111

Still deciding? Get samples first, Contact US !

View similar products

Keyword

- Product description

-

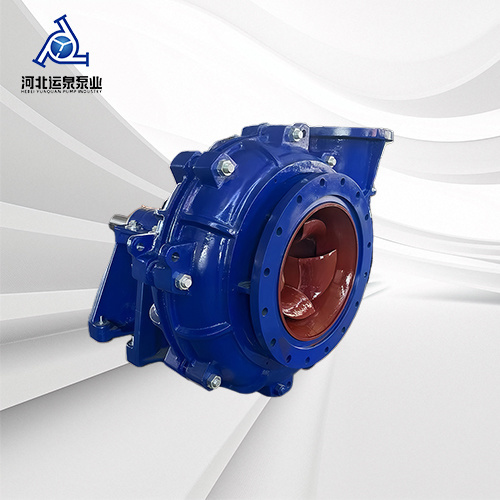

Key Features of ZJ Slurry Pumps

1.Advanced Hydraulic Design

High-efficiency impeller and volute design for optimal slurry transport

Capable of handling large solid particles (up to 50mm)

2.Heavy-Duty Construction

Main components made of high-chrome alloy (Cr26, Cr28, Cr30)

Optional rubber lining available for corrosive applications

Replaceable wear parts (impeller, liner, throat bush)

3.Reliable Shaft Sealing System

Multiple sealing options:

Expeller seal (standard)

Mechanical seal (optional)

Packing seal (traditional)

Extended seal life through optimized flushing systems

4.Robust Bearing Assembly

Large-diameter heavy-duty bearings

Grease or oil lubrication options

Designed for high radial and axial loads

5.Maintenance-Friendly Design

Back pull-out structure for easy maintenance

Interchangeable components to reduce downtime

Technical Specifications

Parameter Range/Value Inlet Size 25-450mm (1"-18") Flow Capacity 10-5000 m³/h (44-22,000 GPM) Head 10-80m (33-262 ft) Max. Solids Up to 60% by weight Particle Size ≤50mm Speed 600-1800 RPM Motor Power 5.5-1500 kW (7.5-2000 HP) Pressure Rating Up to 16 bar (232 psi) Common Applications

Mining Industry: Tailings transport, ore slurry pumping

Metallurgical Industry: Slag handling, abrasive slurry transfer

Coal Industry: Coal washing, coal slurry transportation

Power Plants: Ash handling, FGD systems

Dredging: Sand, gravel, and silt pumping

Comparison with Similar Models

Model Advantages Typical Use Cases ZJ Highest efficiency, longest wear life Large-scale mining operations AH Cost-effective, compact General slurry applications L Rubber-lined option Corrosive slurries Maintenance Guidelines

1.Regular Inspection

Check wear parts every 500 operating hours

Monitor bearing temperature and vibration

2.Seal Maintenance

Ensure proper flush water pressure (for mechanical seals)

Adjust packing gland periodically

3.Lubrication

Replenish grease every 2000 hours

Change oil every 4000 hours (oil-lubricated models)

4.Manufacturer Information

Originally developed by Chinese manufacturers

Comparable to international models:

Warman® AH series (Weir Minerals)

Metso L series

GIW LSA series

Selection Considerations

1.Determine slurry characteristics (abrasiveness, corrosiveness)

2.Calculate required flow and head

3.Choose appropriate material (chrome alloy vs rubber-lined)

4.Select proper sealing system based on operation conditions

150ZJ-I-A50

Email:

Still deciding? Get samples first, Contact US !

View similar products

Keyword

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products