Share to

14-12ST-AH

Hotline:

86-18730251111

Still deciding? Get samples first, Contact US !

View similar products

- Product description

-

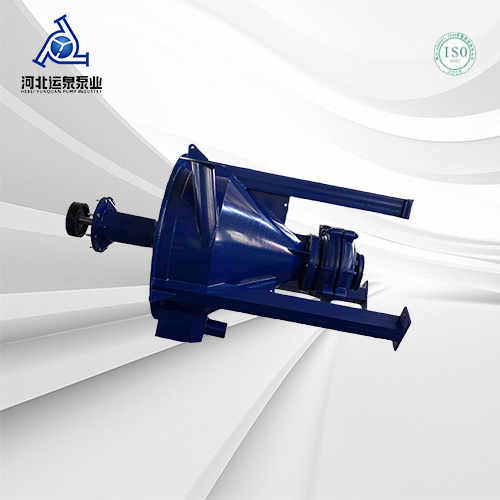

Key Features of YQH Slurry Pumps

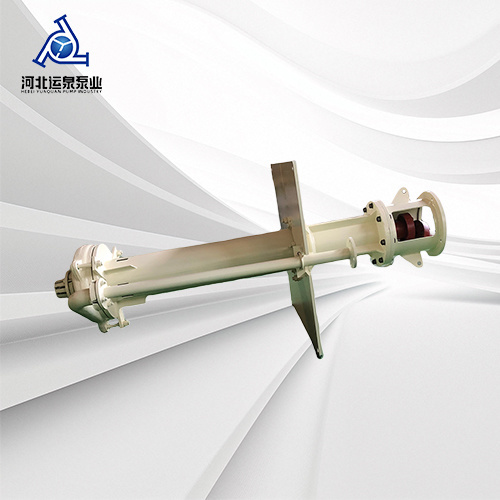

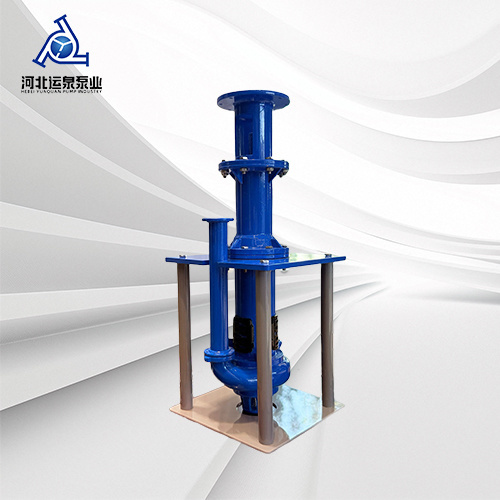

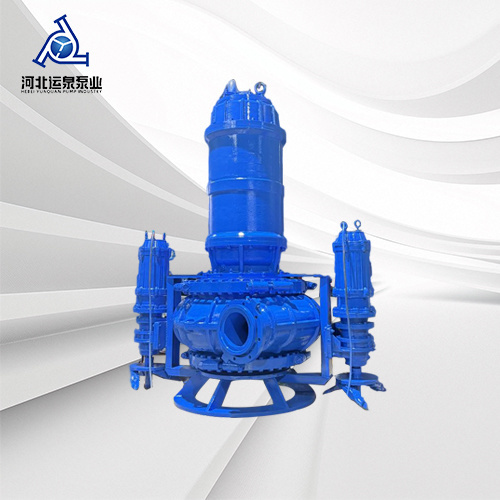

1.Vertical Submerged Design

Operates underwater, eliminating priming issues.

Ideal for sumps, tanks, and pits (e.g., coal slurry pools, mining tailings).

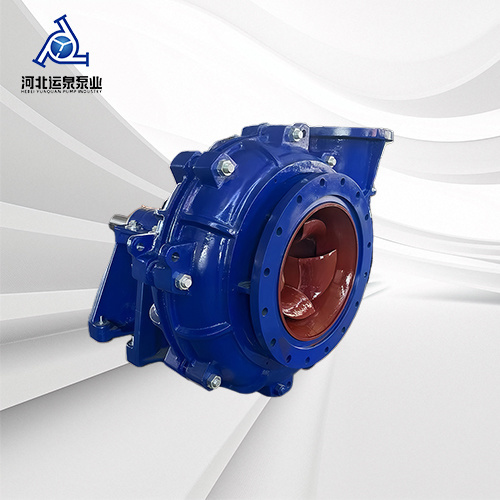

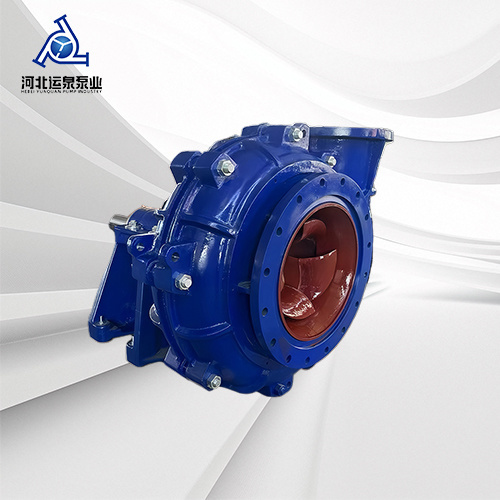

2.Robust Construction

Materials: High-chrome alloy (Cr27, Cr30), rubber lining, or Ni-Hard for wear resistance.

Wet Parts: Replaceable impeller, liner, and throat bush for extended service life.

3.Efficient Hydraulics

Semi-open or closed impeller design for handling large solids (up to 50mm).

High head and flow capabilities for demanding slurry transport.

4.Sealing System

Mechanical seal or packing gland options.

Some models include agitation blades to prevent solids settling.

5.Easy Maintenance

Modular design allows quick replacement of wear parts.

No need to dismantle pipelines for servicing.

Technical Specifications (Typical YQH Model)

Parameter Range Inlet Size 25–300mm (1"–12") Flow Rate 10–2000 m³/h (44–8,800 GPM) Head 10–60m (33–197 ft) Max. Solids Up to 60% by weight Particle Size ≤50mm (depends on model) Motor Power 5.5–450 kW (7.5–600 HP) Speed 600–1800 RPM Common Applications

Mining: Tailings transport, ore slurry pumping.

Coal Washing: Submerged coal slurry handling.

Dredging: Sand, silt, and gravel extraction.

Metallurgy: Slag and abrasive chemical slurry transfer.

Comparison to Other Slurry Pumps

Type YQH Advantages Limitations Horizontal (AH/QV) Better for dry installation Requires priming Submerged (YQH) No priming, compact footprint Limited to submerged use Maintenance Tips

1.Regularly check wear parts (impeller, liner) for erosion.

2.Ensure seal water supply (if using mechanical seals).

3.Monitor motor temperature to prevent overheating.

Manufacturer Variations

Chinese brands (e.g., Shijiazhuang Depon Pump) commonly produce YQH pumps.

Comparable to Warman VSG or Metso VASA vertical pumps.

14-12ST-AH

Email:

Still deciding? Get samples first, Contact US !

View similar products

Keyword

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products