Share to

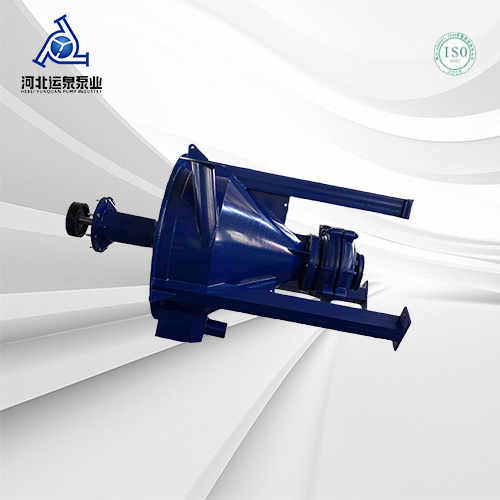

QJS10/8G-G

Hotline:

86-18730251111

Still deciding? Get samples first, Contact US !

View similar products

- Product description

-

Key Features

✔ Fully Submersible – Can operate underwater (up to 10–20m depth, depending on model).

✔ High Abrasion Resistance – Made of high-chrome alloy (Cr27, Cr30) or rubber-lined for wear protection.

✔ Large Solids Handling – Capable of pumping gravel, stones, and solids up to 50–80mm.

✔ Agitator Option – Some models include a built-in agitator to stir settled solids.QSG Submersible gravel pump

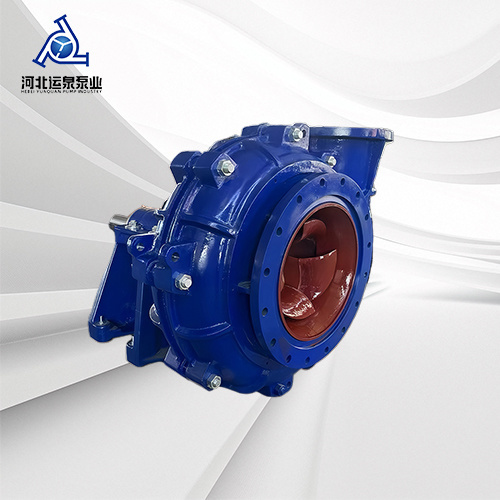

QSG Submersible Gravel Pump - Technical Specifications & Features

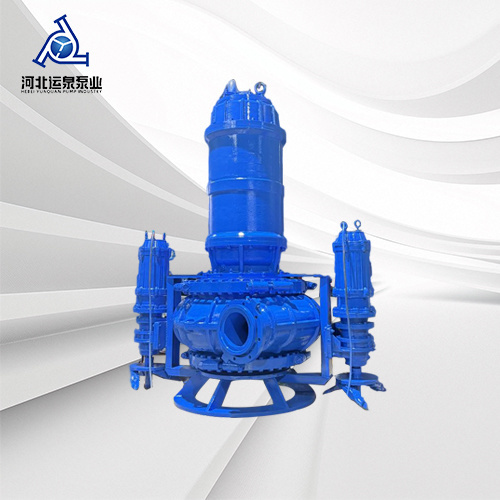

The QSG submersible gravel pump is a heavy-duty, fully submersible dredge pump designed for sand, gravel, and high-solid slurry applications in mining, dredging, and construction.

Key Features

✔ Fully Submersible – Can operate underwater (typically 5–25m submersion depth).

✔ High Chrome Alloy Construction – Impeller & volute made of Cr27, Cr30, or A49 alloy for extreme wear resistance.

✔ Large Solids Handling – Passes 50–100mm rocks/gravel (depends on model).

✔ Agitator Option – Some models feature rotating agitators to prevent solids settling.

✔ Robust Seal System – Double mechanical seals + oil chamber for underwater reliability.

✔ Explosion-Proof Motor – Available for hazardous environments (coal mines, oil sands).Typical Applications

River & Sea Dredging – Sand extraction, sediment removal.

Mining & Tailings – Slurry pumping in gold, iron ore, and coal mines.

Construction Dewatering – Handling gravel-laden water in tunnels & foundations.

Sand Washing Plants – Recirculating abrasive slurries.

Technical Specifications

Parameter Range Flow Rate 50–1500 m³/h (220–6,600 GPM) Head 10–60m (33–200 ft) Max. Solids Up to 70% by weight Particle Size Up to 100mm (4") Motor Power 7.5–400 kW (10–530 HP) Voltage 380V, 415V, 660V, 3-phase Submersion Depth Up to 25m (special models) Comparison: QSG vs. Standard Submersible Pumps

Feature QSG Gravel Pump Standard Submersible Pump Solids Handling Up to 100mm gravel Max 10–20mm solids Wear Resistance High-chrome alloy Cast iron/stainless steel Agitator Option Yes (prevents clogging) Rarely available Typical Use Dredging, mining Sewage, drainage Maintenance & Lifespan

Wear Part Lifespan (in abrasive slurry):

Impeller: 800–1,500 hrs

Seals: 3,000–5,000 hrs

Motor: 10,000+ hrs (with proper cooling)

Maintenance Tips:

Regularly check oil in seal chamber.

Clean cooling jacket to prevent overheating.

Inspect cable integrity (submersion damage risk).

QJS10/8G-G

Email:

Still deciding? Get samples first, Contact US !

View similar products

Keyword

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products