Share to

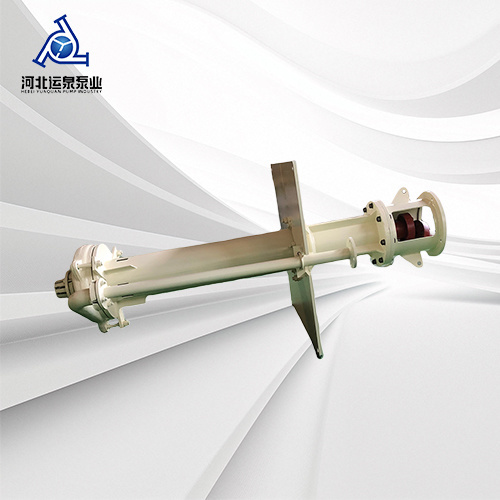

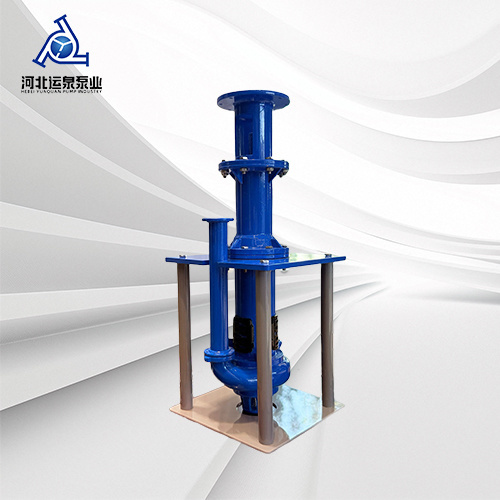

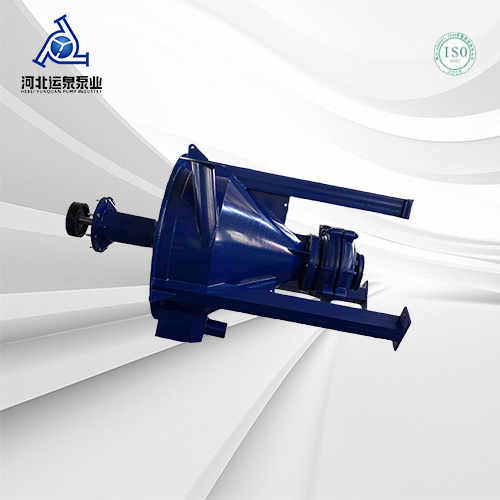

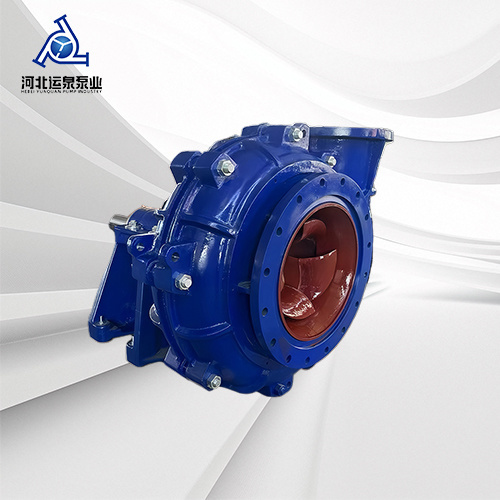

65ZJL-A30

Hotline:

86-18730251111

Still deciding? Get samples first, Contact US !

View similar products

Keyword

- Product description

-

Design Features

Vertical cantilever design: Eliminates submerged bearings, reducing maintenance

Single-stage, single suction: Optimized for vertical slurry transport

Modular construction: Allows easy replacement of wear components

Compact footprint: Ideal for sump and pit applications

Optional agitator: Prevents solids settling in sumps (ZJLA variant)

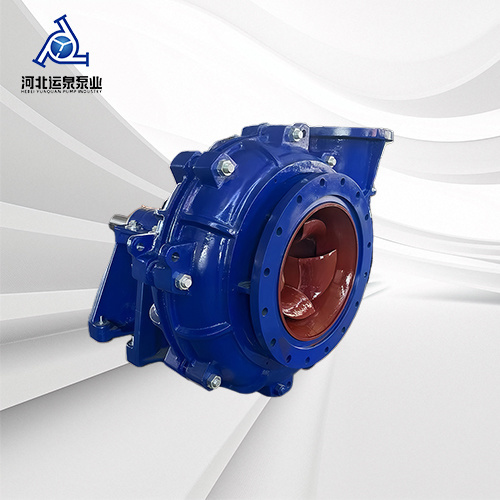

Construction Materials

Component Material Options Application Suitability Impeller A05 high-chrome alloy (Cr27) Highly abrasive slurries Natural rubber Corrosive, medium abrasion Ceramic composite Extreme wear applications Liner Cr15Mo3 alloy General abrasive service Polyurethane Corrosive/abrasive combo Shaft 420 stainless steel Standard service 2507 duplex stainless Severe corrosive environments Performance Specifications

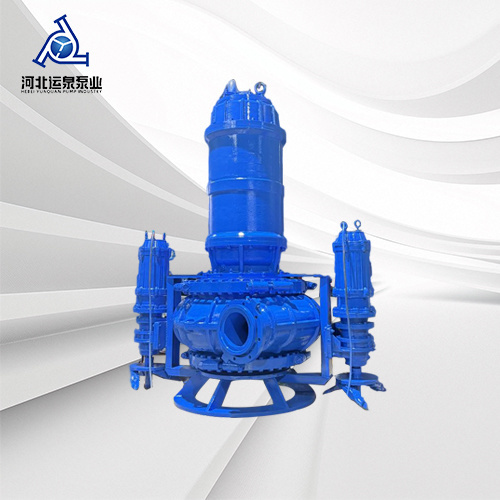

Parameter Range Max. Capacity Flow rate 15-2500 m³/h 2800 m³/h (special) Head 8-60m 75m (special) Solids handling Up to 70% by weight Particle size ≤80mm Temperature -20°C to +140°C Operating pressure ≤1.6MPa Sealing Systems

Standard: Expeller + packing gland combination

Premium: Double mechanical seals with API plan 54

Special: Cartridge seal arrangement for easy maintenance

Flush options: External flush, barrier fluid, or process liquid

Drive Options

Direct drive: 4/6/8 pole motors (1500/1000/750 RPM)

Belt drive: Adjustable speed configurations

Custom: Explosion-proof or variable frequency drives

Applications

Mining:

Tailings disposal (up to 65% solids)

Mill discharge pumping

Heap leach applications

Power:

Bottom ash handling

FGD slurry recirculation

Industrial:

Mineral processing

Dredging operations

Sand and gravel extraction

Technical Advantages

50% longer wear life compared to conventional designs

20% energy savings through optimized hydraulics

Quick-change impeller system reduces downtime by 70%

Triple-bearing support for enhanced shaft stability

Anti-clogging impeller design for fibrous materials

Maintenance Features

Top-access maintenance: No need to disassemble piping

Modular wear parts: Liner, impeller, throat bush replacement in <4 hours

Lubrication-free bearings: For models ≤200kW

Shaft deflection monitoring: Optional vibration sensors

65ZJL-A30

Email:

Still deciding? Get samples first, Contact US !

View similar products

Keyword

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products