Share to

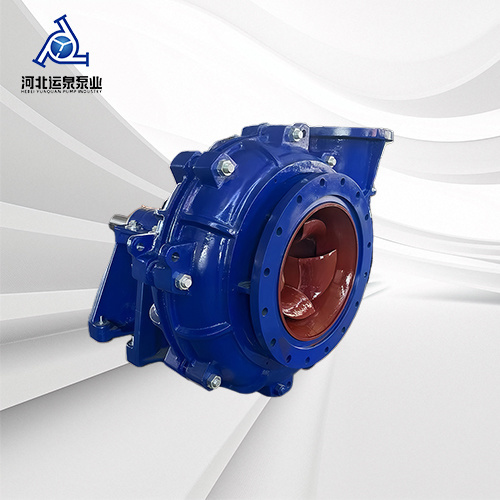

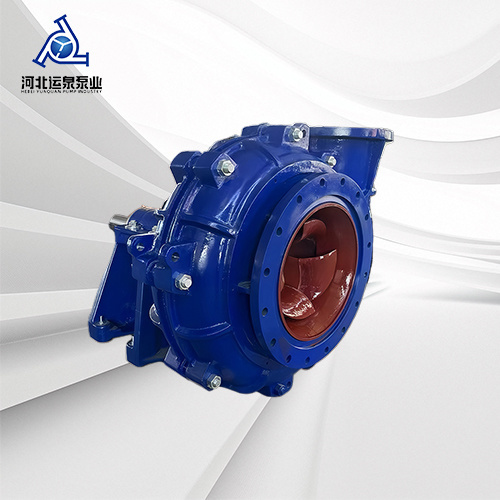

6/4D-G

Hotline:

86-18730251111

Still deciding? Get samples first, Contact US !

View similar products

- Product description

-

Key Features

✔ Robust Construction – High-chrome alloy (Cr27, Cr30), rubber-lined, or Ni-Hard materials for extended wear life.

✔ Large Solids Handling – Capable of pumping particles up to 50–100mm (depending on model).

✔ Heavy-Duty Bearings – Grease or oil-lubricated for high-load conditions.

✔ Easy Maintenance – Back pull-out design for quick impeller and seal replacement.

✔ Multiple Sealing Options – Expeller, mechanical, or gland packing seals.Typical Applications

-

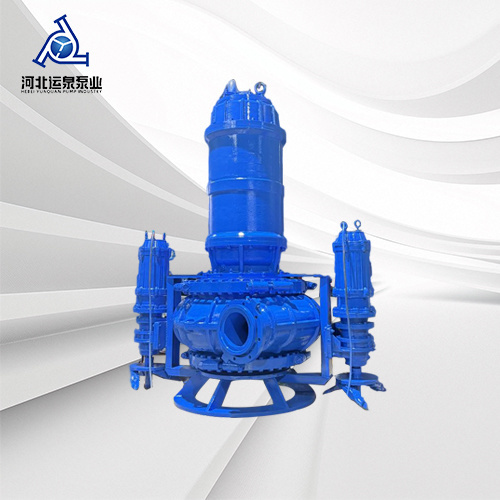

Sand & Gravel Dredging – River, lake, and sea dredging operations.

-

Mining & Mineral Processing – Tailings transport, ore slurry pumping.

-

Construction – Slurry transfer in tunneling and foundation work.

-

Coal Washing Plants – Handling coal slurry with high solids content.

Technical Specifications

Parameter Range Inlet Size 50–300mm (2"–12") Flow Rate 20–3000 m³/h (90–13,200 GPM) Head 10–60m (33–200 ft) Max. Solids Up to 70% by weight Particle Size Up to 100mm (4") Motor Power 15–1000 kW (20–1350 HP) Speed 600–1800 RPM Common Models & Equivalents

Model (Chinese OEM) Warman Equivalent Metso Equivalent G(GH) Series Warman AH Metso L Series H(HH) Series Warman M Metso MDM Series SP Series Warman SP – Selection Guide

A. Choose the Right Material

-

High-Chrome Alloy (A05, A49, Cr27, Cr30) – Best for highly abrasive slurries (e.g., sand, gravel).

-

Rubber-Lined (Natural, Neoprene) – Better for corrosive slurries with medium abrasion.

-

Ni-Hard – Extreme wear resistance for long-term heavy-duty use.

B. Select the Proper Seal Type

-

Expeller Seal – Default for abrasive slurries (no external water needed).

-

Mechanical Seal – For fine slurries (requires clean flush water).

-

Gland Packing – Low-cost option but requires regular adjustment.

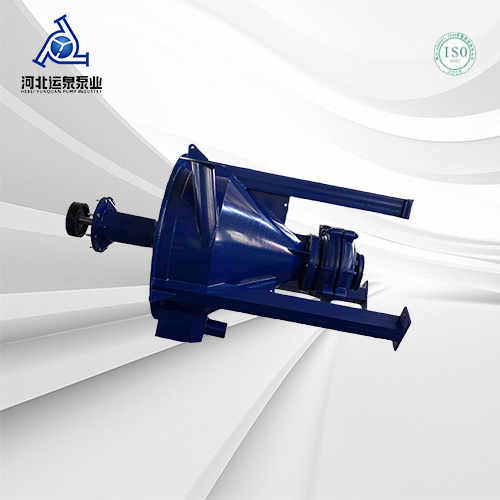

C. Determine Drive Configuration

-

Direct Coupling – For fixed-speed applications.

-

Belt Drive – Allows speed adjustment for varying conditions.

-

Hydraulic Drive – Used in mobile dredging setups.

-

6/4D-G

Email:

Still deciding? Get samples first, Contact US !

View similar products

Keyword

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products